Automatic Air Filter Making Machine Knife Pleating Style Folding Machine

Our Automatic Air Filter Making Machine with Knife Pleating Style Folding is designed for high-precision and efficient production of air filters. Featuring advanced knife pleating technology and an intelligent control system, this machine ensures uniform and accurate pleats, enhancing filter performance. With robust construction, easy operation, and energy-efficient design, it is ideal for producing various types of air filters with consistent quality.

- Overview

- Inquiry

- Related Products

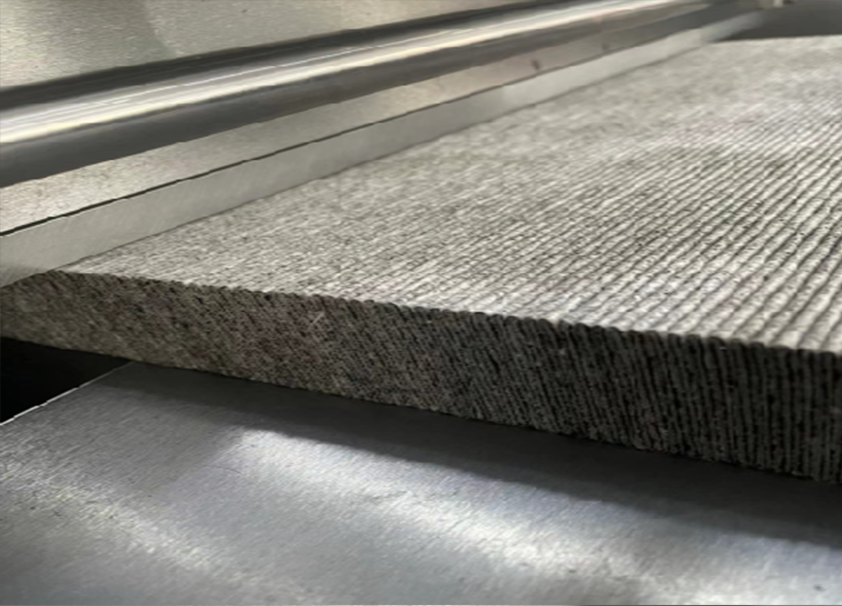

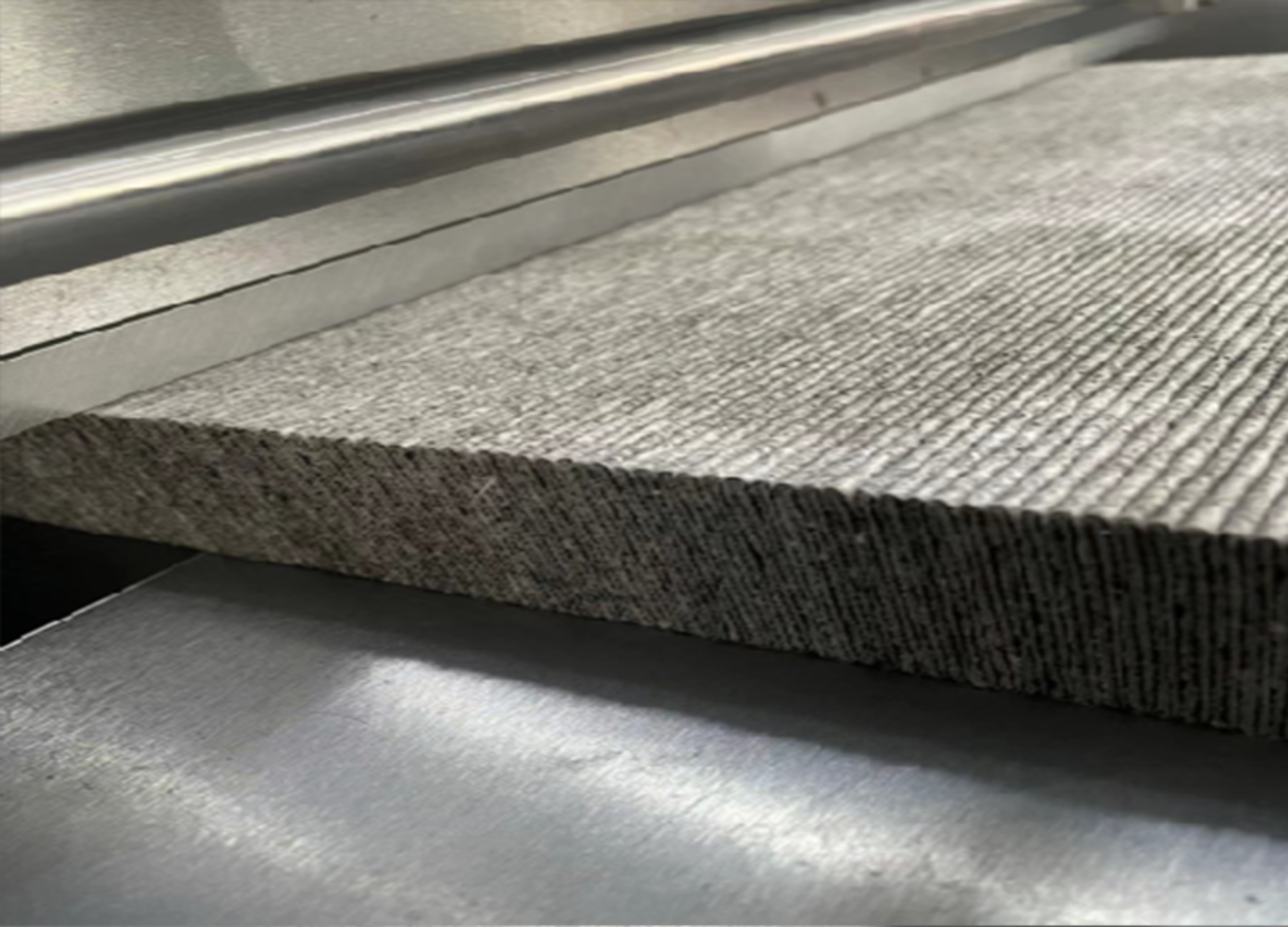

The equipment is mainly used for the production of chemical fiber and synthetic filter material folding. It is equipped with a fully automatic adjustment system, which can automatically match when changing the folding height. The adjustable operation curve of the folding knife (servo control) adapts to the folding of different materials. The ball screw drive mechanism has low noise, fast speed and easier operation.

Selectable width:700mm/1000mm/1300mm/1500mm

FEATURES

● Processing width:680mm

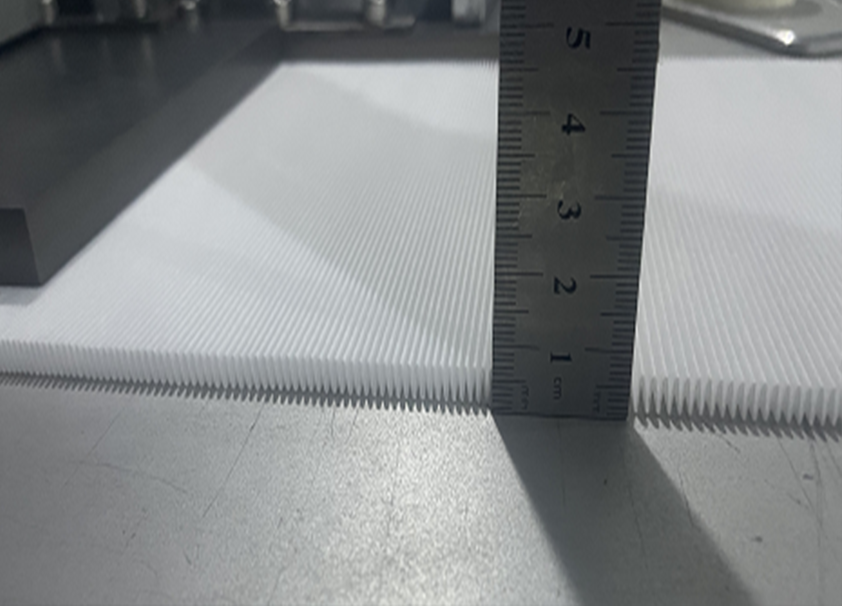

● Paper folding height:5-70mm(The maximum folding height of 150mm can be selected)

● Operating mechanism: ball screw, crank arm

● Average speed for the production line:150 folds/min

● Paper folding principle: the upper and lower knives driven by servo motor reciprocate

● Paper folding height adjustment: touch screen parameter setting, full automatic adjustment

● Paper folding discharge plate height adjustment: touch screen parameter setting, full automatic adjustment

● Material heat setting: 2 sets of automatic thermostats for feeding and forming sections

● Tension control: automatic tension control system

● Cutting machine: automatic feeding machine with cutting device

● Mechanical framework:dimension:5500mmX1500mmX1700mm(LXWXH)

● Power:12KW

● Weight:2000KG

● Folding type: regular, high and low folding, progressive folding, self-set folding height

APPLICATIONS

1.HVAC Systems

This machine is essential for producing pleated air filters used in heating, ventilation, and air conditioning (HVAC) systems. These filters improve indoor air quality by capturing dust, pollen, and other airborne particles, ensuring cleaner air circulation in residential, commercial, and industrial buildings.

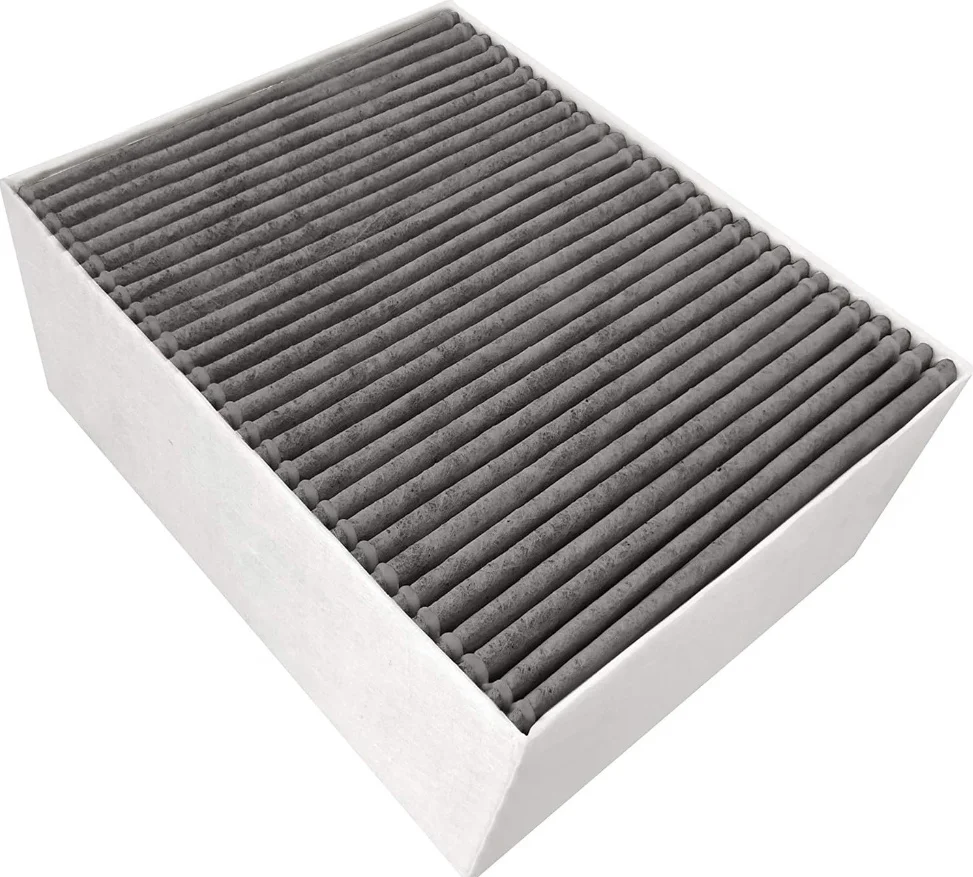

2.Automotive Cabin Air Filters

The machine is used to manufacture pleated air filters for automotive applications. These filters trap pollutants such as dust, pollen, and exhaust gases, providing cleaner air inside vehicle cabins and enhancing passenger comfort and health.

3.Industrial Air Filtration

In industrial settings, air filtration is crucial for protecting machinery, products, and workers from airborne contaminants. This machine produces durable pleated filters that can withstand harsh industrial environments, making them ideal for use in factories, workshops, and manufacturing plants.

4.Medical and Healthcare Facilities

The machine is used to produce high-efficiency pleated filters for medical and healthcare environments. These filters help maintain sterile conditions in hospitals, clinics, and laboratories by removing bacteria, viruses, and other harmful particles from the air.

5.Cleanrooms and Controlled Environments

Industries such as pharmaceuticals, biotechnology, and electronics rely on cleanrooms with controlled environments. This machine produces the specialized pleated filters needed to maintain extremely low levels of airborne particulates, ensuring product quality and safety.

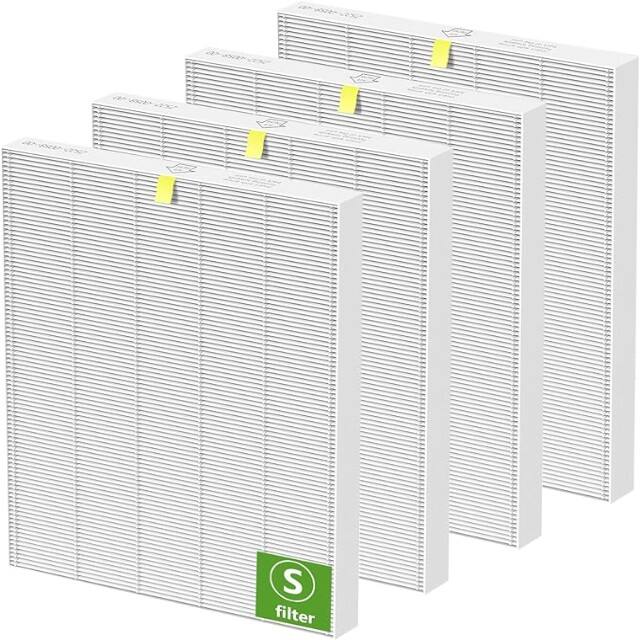

6.Home Air Purifiers

With growing concerns about indoor air quality, this machine is used to produce pleated filters for home air purifiers. These filters help reduce allergens, dust, pet dander, and other pollutants, promoting healthier living spaces for individuals and families.

7.Commercial Air Purification Systems

Businesses and public spaces such as offices, schools, and shopping centers benefit from advanced air purification systems. The machine produces pleated filters that enhance these systems' efficiency in removing contaminants, thus improving overall air quality and occupant health.

8.Paint Booths and Spray Rooms

The machine is vital for creating filters used in paint booths and spray rooms. These filters capture overspray and airborne particles, ensuring a cleaner working environment and preventing contamination of painted surfaces.

9.Food and Beverage Industry:

Air quality is critical in food and beverage production to prevent contamination and ensure product safety. This machine produces pleated filters that help maintain clean air in production and packaging areas.

10.Aerospace and Defense

The aerospace and defense sectors require highly efficient air filtration systems for aircraft and other sensitive environments. The machine produces the pleated filters necessary to maintain air quality and protect sensitive equipment and personnel.

PRODUCT DETAILS