Efficient Filtration Solutions Driving Industry Advancement

A wide spectrum of industrial and environmental processes require filter rolls to ensure that a variety of fluids, gases, and particulates are pure and of high quality. These versatile rolls made from various materials designed for particular uses have become an indispensable tool in water treatment, air pollution control, pharmaceutical production, food processing etc.

Part 1: Know Your Filter Rolls

Filter material rolls are continuous lengths of preformed filter media that can be easily integrated into filtration systems. They are characterized by high surface area, durability, as well as tailor-made porosity which is efficient enough to remove impurities without much resistance to fluid or gas flow. The choice between synthetic; natural; membrane; or composite depends on the intended application and the specific contaminants to be filtered.

Part 2: Breakthroughs in the Field of Filter Rolls

Nanotechnology Integration: Recent progress has seen nanotechnology being incorporated into filter rolls. These rolls can be made more efficient through the introduction of nanoparticles or nanostructured surfaces especially when dealing with submicron particles thus making them suitable for advanced applications requiring ultra-high purity.

Environmentally friendly material: Sustainable and biodegradable materials are increasingly being used in filter media. This helps in reducing the environmental impacts related with filtration process while at the same time aligning with global efforts towards circular economy practices.

Multi-layer design: Multi layer filter media rolls have been developed to tackle complex filtration challenges. Each layer is optimized for a specific filtration task thereby improving overall performance and prolonging service life.

Self-cleaning capabilities: Advanced filters include self-cleaning mechanisms such as hydrophobic coatings or electrochemical treatments that allow them clean themselves automatically during use hence minimizing maintenance needs and downtime.

Section 3: Applications of filter roll materials

Water Treatment System : In order to make drinking water safe for human consumption and protect aquatic ecosystems, suspended solids, bacteria, viruses and other impurities are removed from water using filter roll materials in water purification systems.

Air Pollution Control: Industrial settings rely on these rolls to capture particulate matter (PM), Volatile Organic Compounds (VOC’s) and other contaminants present in the exhaust gases resulting to better air quality.

Pharmaceutical industry: The pharmaceutical industry relies on high performance filter roll materials to ensure sterility of raw materials, intermediates and final products due to its strict hygiene standards.

Food and Beverage Processing: Food manufacturers employ filter rolls during their processing stages to maintain product quality by removing impurities and preventing contaminations.

Conclusion:

Filter rolls are a testament of continual search for more environmentally friendly industrial processes. Hence as material science, design and technology continue progressing, these versatile tools will become increasingly important in shaping the future of filtration for advancing industries while still conserving the earth’s resources.

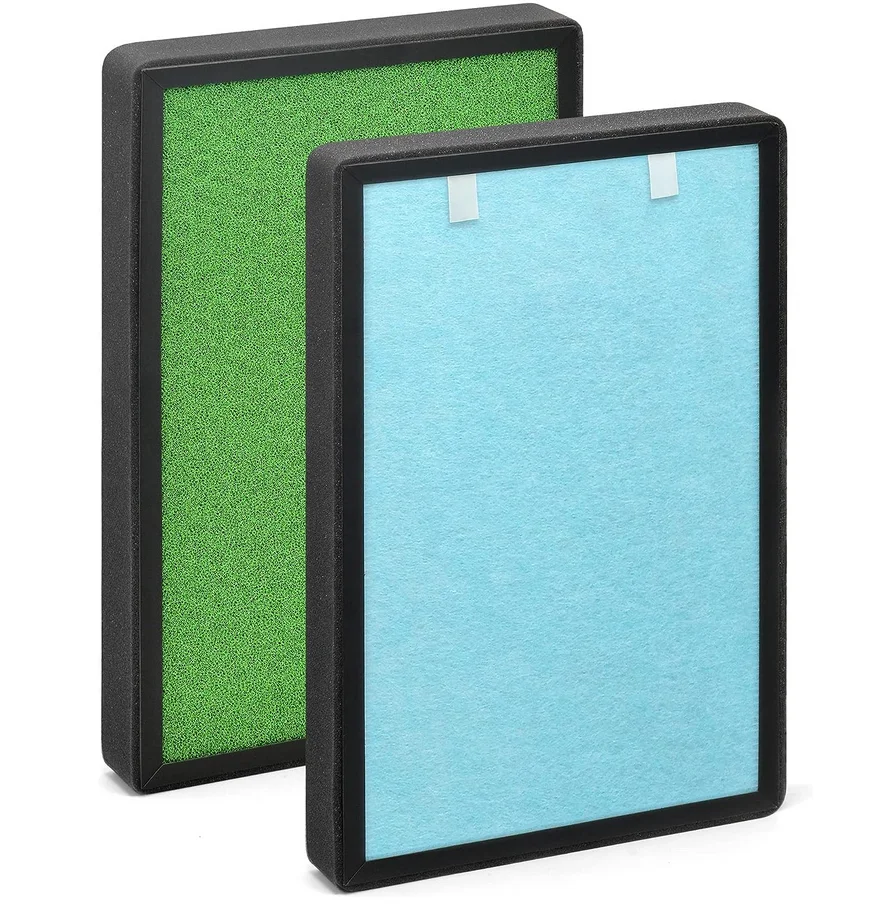

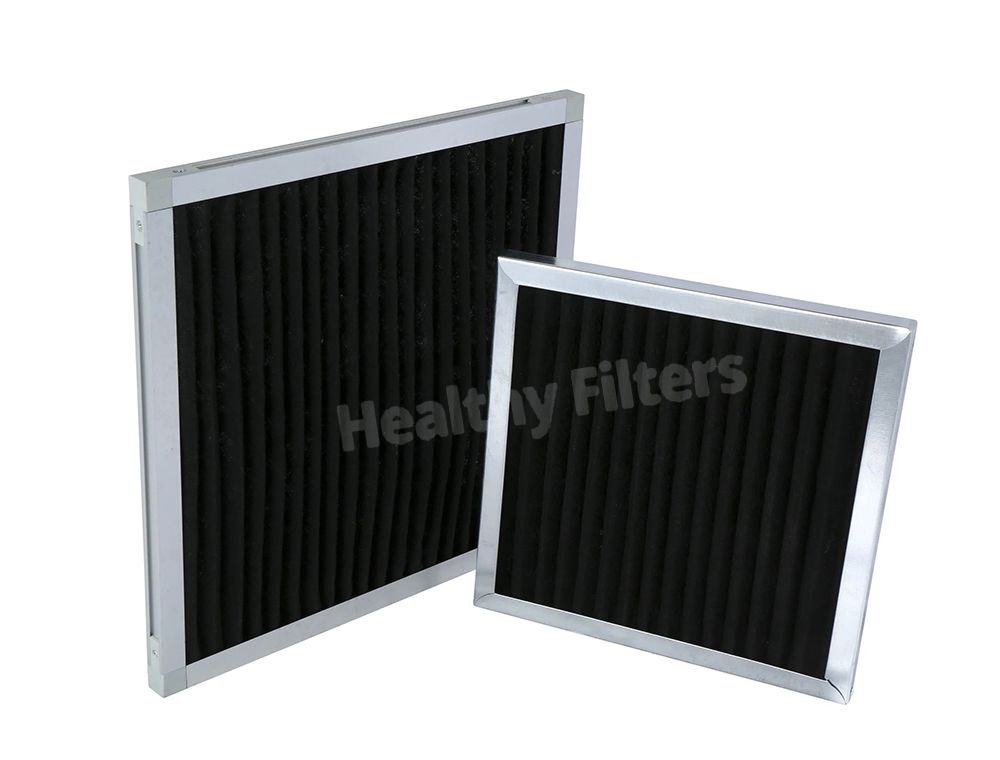

Recommended Products

Hot News

-

What You Need to Know About AIRCARE Humidifier Filters

2024-01-24

-

Filtration Show 2023 USA

2023-12-13

-

Filtech 2024 Germany

2023-12-13

-

Obtain Patent Certificate

2023-12-13