Healthy Filters Factory Supply High Quality H13 H14 U15 FFU Hepa Filter with Fan for Clean Room

FFU (Fan Filter Unit) is an air purification device utilized to supply clean air to cleanrooms in semiconductor plants, liquid crystal diode facilities, and other similar environments. It is typically installed on the grid ceiling system. In extensive cleanroom settings, hundreds to thousands of these units are required for efficient operation.

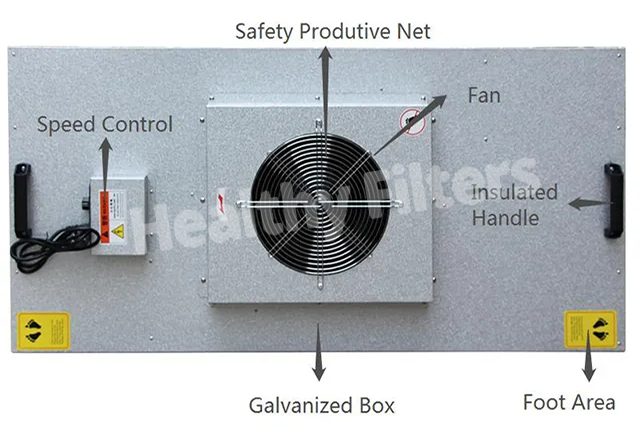

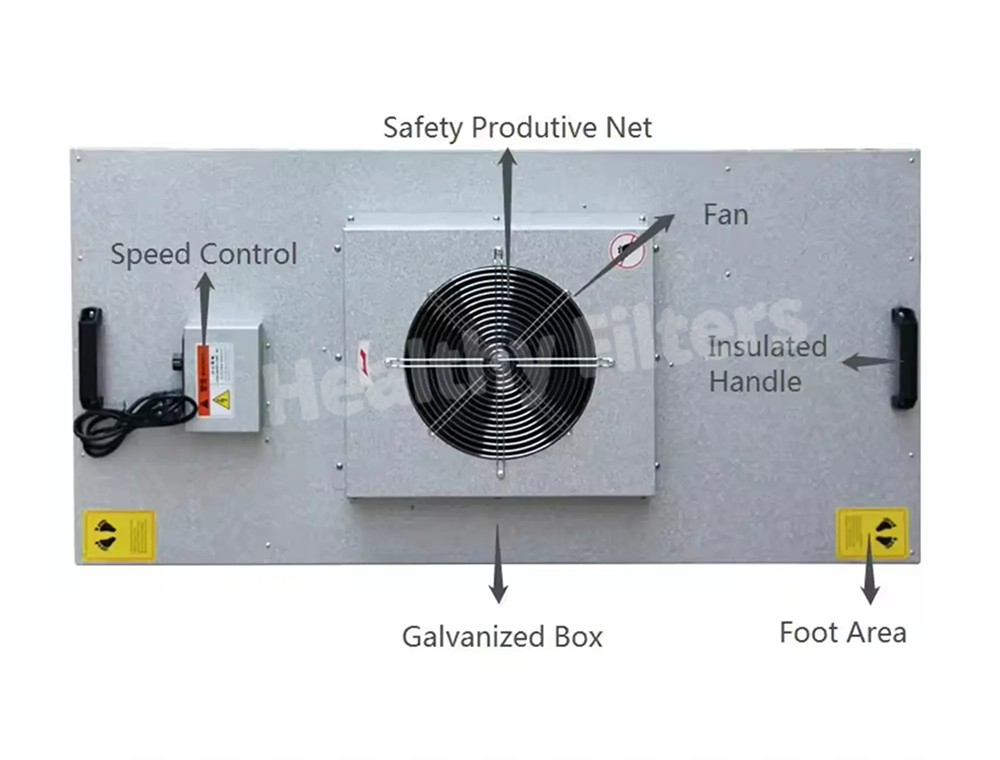

1. High-Quality Construction: Made from durable materials, our FFU is designed to withstand continuous use and maintain its performance over time.

2. Integrated Fan: The built-in fan ensures a consistent and efficient airflow, maintaining optimal air circulation and filtration performance in your clean room.

- Overview

- Parameter

- Inquiry

- Related Products

An FFU, also known as a fan filter unit, is motorized air filtering equipment that supplies purified air to cleanrooms, laboratories, medical facilities, or microenvironments. These units effectively eliminate harmful airborne particles from recirculating air. They are typically installed within the ceiling or floor grid of the system.

FEATURES

● High Energy Efficiency

● High Airflow Capacity

● Quick and Easy Commissioning

● Complete Control and Monitoring

● Size customization available

Low Consumption and High Performance: Featuring a direct drive backward inclined fan, this unit offers high efficiency, low noise, and enhanced durability, making it more energy-saving and cost-effective to operate.

Scientific Air Passage Design: The design of the air passage minimizes resistance and noise while saving space.

Flexible Customization: Our equipment is highly adaptable to meet various requirements. The external size can be modified to fit different GRID types, and we offer professional solutions to accommodate changes in external casing materials, special power supplies, or fan configurations.

Safe and User-Friendly Operation: The FFU is designed to support high-intensity boxes, ensuring staff safety during installation and maintenance. It also supports remote monitoring and adjustment, making it easy to operate.

Multi-Level Protective Devices: The FFU includes over-current relays, motor protection devices, fault indicators, and fault signal circuits. Additionally, thermal protectors, fuses, and motor breakers can be added upon request.

APPLICATIONS

The FFU is designed for cleanrooms, pharmacies, pharmaceutical manufacturing facilities, and laboratories. It provides high volumes of HEPA or ULPA filtered air at low noise levels, while reducing energy consumption by 15 to 50% compared to similar products.

SPECIFICATIONS

| Item Name | Hepa fan filter unit |

| External Frame | stainless steel or Galvanized steel with aluminum painting |

| Fan | low vibration, low noise, imported or domestically fan |

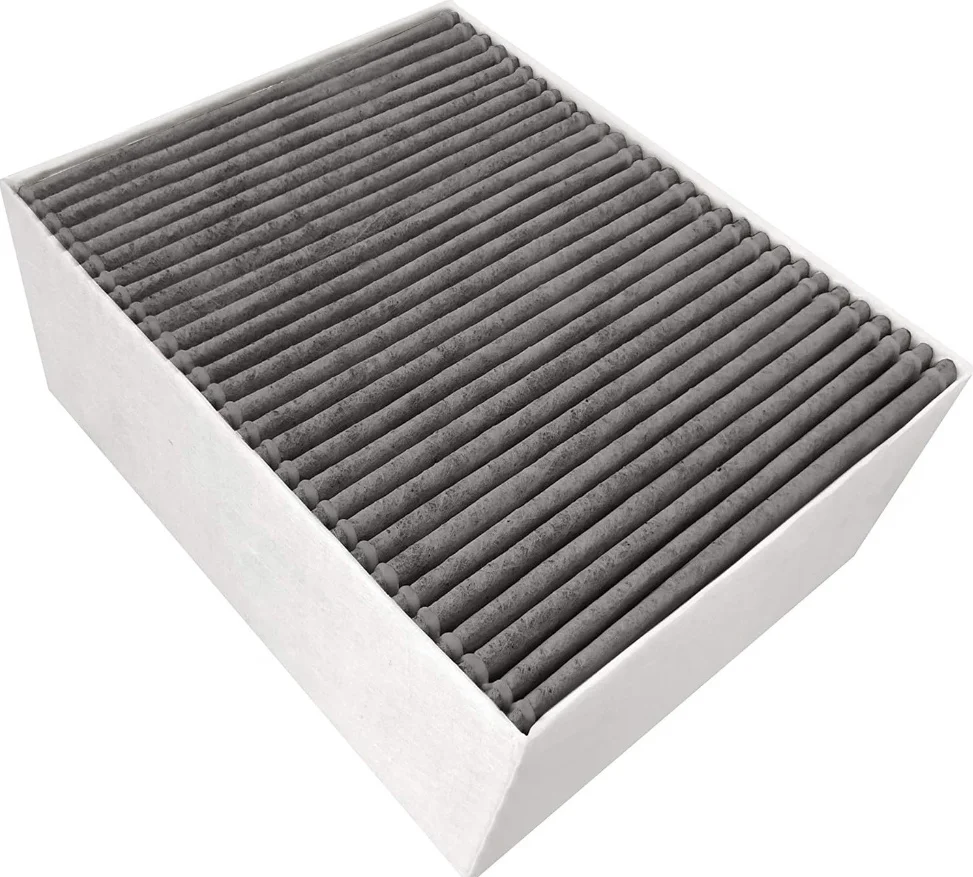

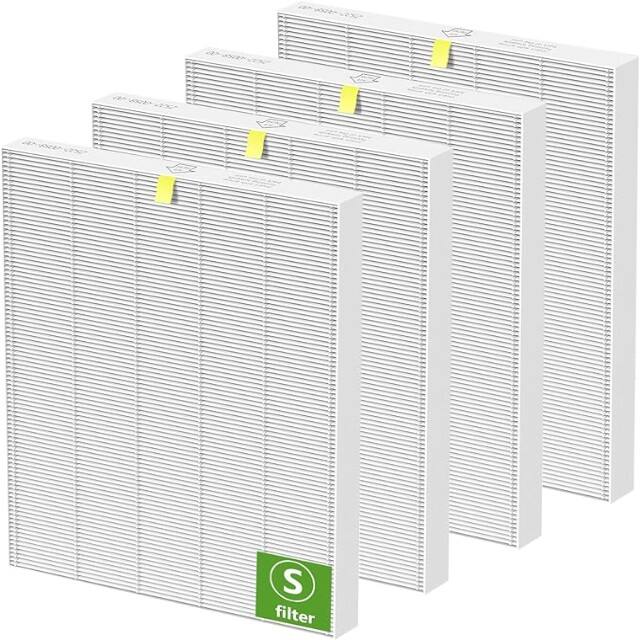

| Media | Chinese filter paper or HV filter paper |

| Wind speed | 0.4-0.8m/s can adjustable |

| HEPA efficiency | 99.99%@0.3um ~ 99.999%@0.3um |

| Air flow | 1000-2000m³/h |

| System control mode | AC and DC |

| Max. operating temp. | 80 degree Celsius |

| Humidity | 80% |

| Noise Db(A) | ≤57dB |

| Motor | 220V 50Hz, 1phase |

PRODUCT DETAILS