Importance of Filter Material Rolls in Industrial Applications

In different industries, ranging from water treatment to air purification, use of filter material rolls is important for ensuring that the right quality and safety standards are met when processing or manufacturing goods. For this reason, such rolls made from specific materials for trapping contaminants form the main components in filtration systems.

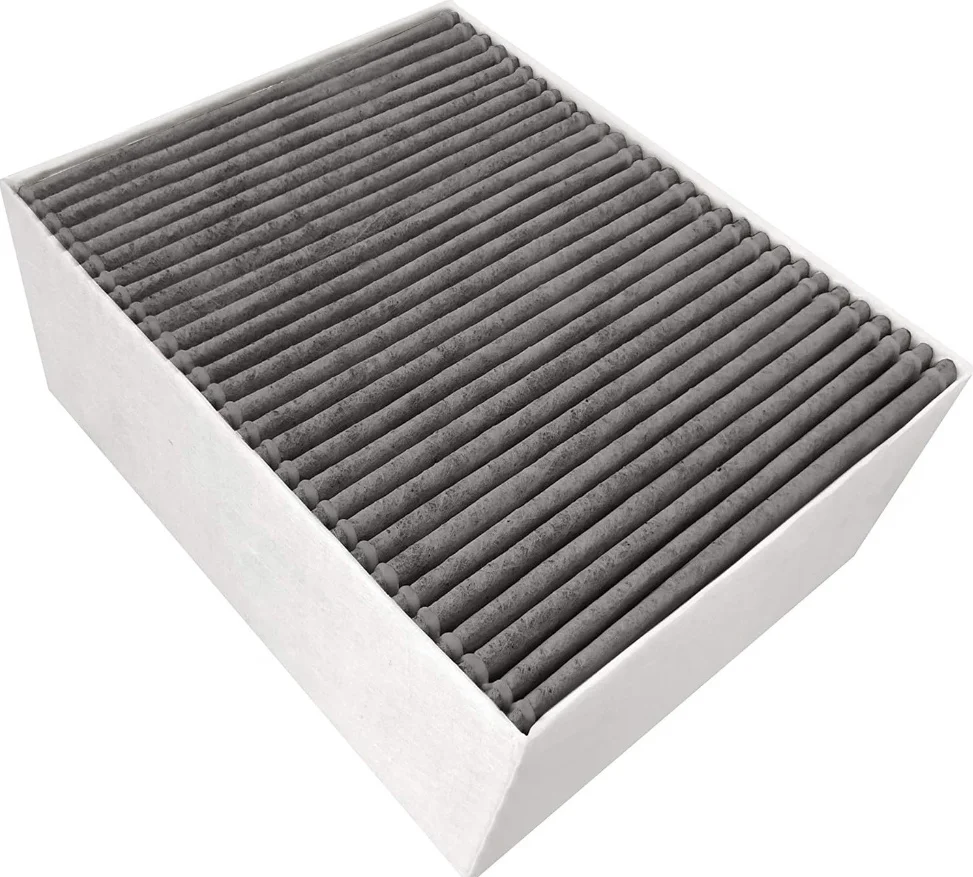

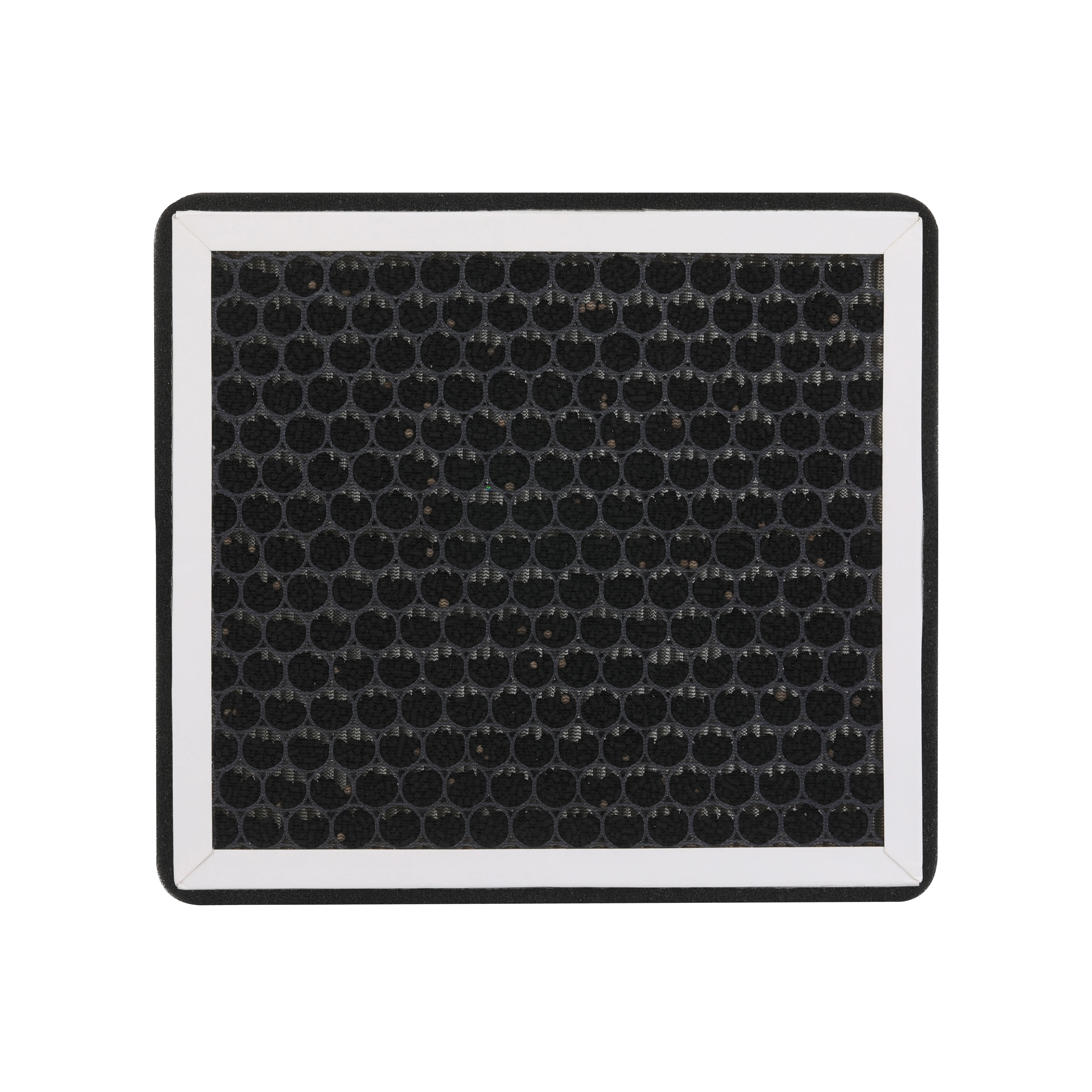

Filter material rolls are made from diverse materials, e.g., activated carbon, fiberglass and various specialized polymers which have been selected according to their particular filtration characteristics. Activated carbon can adsorb organic compounds for example whereas fibreglass has a large surface area so as to capture small particles.

In water treatment industry filter material rolls are used for removing impurities from water making it suitable for drinking or industrial purposes. These filters effectively trap sediment, bacteria and other contaminants producing clean water that can be utilized in different applications.

For air purification purposes, filter material rolls captures dust, pollen grains and other small particles suspended in air that can cause breathing complications. Application of these filters results into improved indoor air quality by reducing dust as well as allergens which may trigger allergies.

The process of coming up with these rolls is high precision engineering in order to meet strict quality parameters. Porosity, thickness and durability are some factors manufacturers must consider before creating an efficient and long lasting product that meets specific requirement.

Moreover, choice of filter material rolls depends on the kind of application involved. This means that there are some specifically designed to operate under high temperatures while others resist chemicals or oils.

Additionally, aside from their functional role, filter material rolls also help towards achieving sustainability goals. They aid in reducing environmental pollution through effective filtration hence preserving delicate ecosystems.

However it should be noted that these consume require regular maintenance and replacement so as to remain effective. Eventually the efficiency will reduce with time due to clogging by impurities such as dusts among others. Henceforth it is imperative to replace them regularly for maximum performance.

In summary, filter material rolls are important parts of several industrial applications that have significant filtration roles. Their design, production and upkeep require precision and professionalism thus indicating the importance of these often overlooked components in our lives every day.

Recommended Products

Hot News

-

What You Need to Know About AIRCARE Humidifier Filters

2024-01-24

-

Filtration Show 2023 USA

2023-12-13

-

Filtech 2024 Germany

2023-12-13

-

Obtain Patent Certificate

2023-12-13