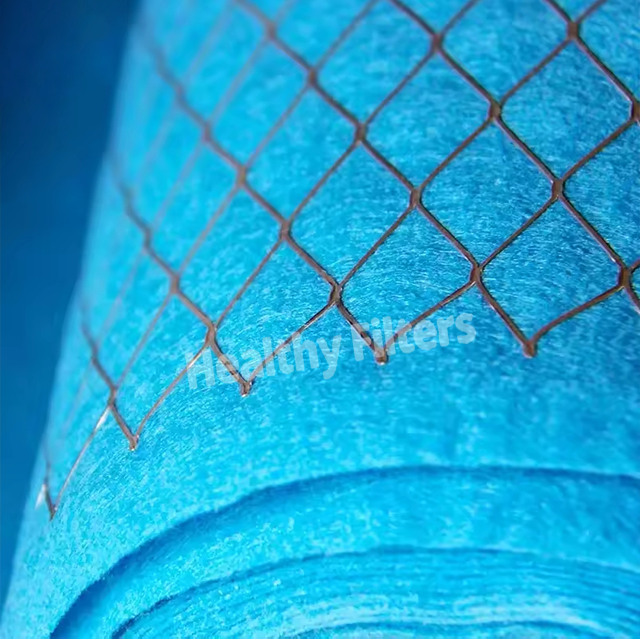

Laminated Mesh Air Filter Media Roll G3 G4 Class Metal Mesh Filter Media With Mesh

The wire filter mesh is made of wire and filter cloth. The material we use is importedpolyester fiber filter material, with different melting points inside and outside with non-directional fiber staggered three-dimensional structure, through acupuncture, adhesive.hot melt process made, divided into junior high efficiency filtration.

This filter media is usually constructed using resilient synthetic fibers that are resistant to breakage. It is strengthened with a mesh layer to enhance its rigidity and structural strength. As a result, it is extremely efficient in environments with significant air pollution and contamination.

- Overview

- Parameter

- Inquiry

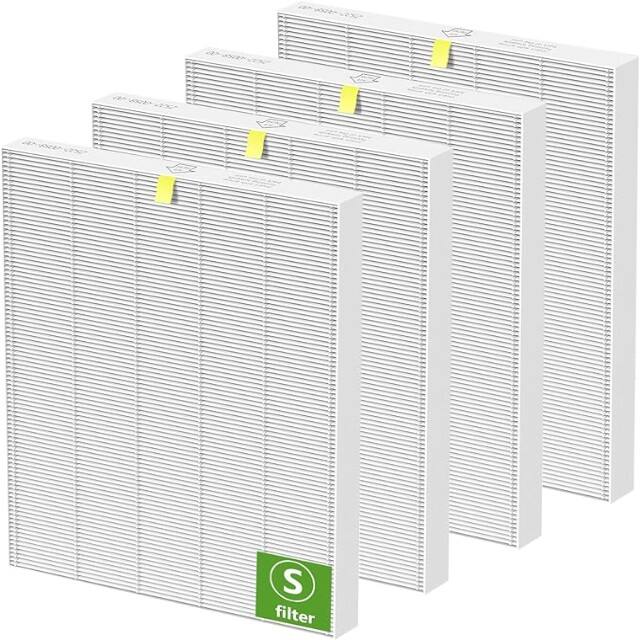

- Related Products

Laminated air filter media rolls, classified as G3 and G4, are crafted from durable, non-breakable synthetic fibers reinforced with a mesh layer. This design enhances the media's stiffness and structural integrity, making it ideal for high-pollution environments. The reinforced structure ensures superior filtration efficiency and a longer filter life, reducing the need for frequent changes and lowering overall costs. These attributes make the media perfect for pre-filters or primary filters in HVAC systems, providing a reliable solution for maintaining clean and healthy air.

FEATURES

● Large Filtration area

● High dust ohlding capacity

● Grade: G3, G4, M5, M6, F7, F8, F9

● Synthetic fibers

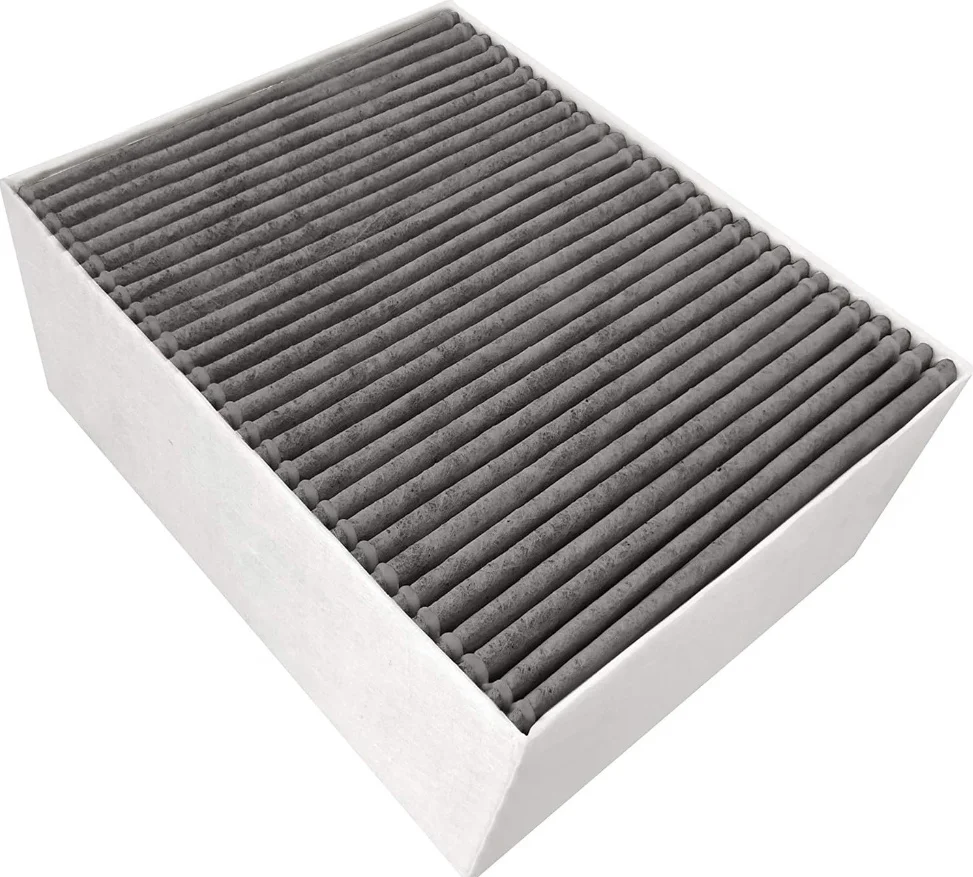

● Frame Options: Cardboard, aluminum and galvanized steel

● Heat resistance: 80℃

● The structure is robust, made from break-resistant PET synthetic fibers, and produced through various processes such as needling, bonding, and thermal bonding methods

● Large filtration area: The filtering section is pleated, which increases the filtration surface area, reduces the resistance of the filter, and results in a longer lifespan compared to flat filters

● Long lifespan: The product features tightly bonded fibers, break resistance, minimal shedding, corrosion resistance, wear resistance, and excellent elastic recovery

● Process characteristics: The polyester fiber filter material uses fibers with different melting points arranged in a non-directional three-dimensional structure. It is produced through processes such as needling, bonding, and thermal melting

APPLICATIONS

Covering cotton can be divided into primary effect covering cotton and medium effect covering cotton. Used as filter media for metal filters such as cardboard frames, aluminum frames, and adhesive frames. Used to produce primary effect plate air filters.

SPECIFICATIONS

| Model | Filter Grade | Filter Efficiency | Resistance (Pa) | Thickness | Filter Media Weight (g/㎡) |

| HF-M8 | MERV 8 | 40-45% | 4 | 1.5mm | 110gsm |

| HF-M11 | MERV 11 | 60-65% | 4 | 2mm | 95gsm |

| HF-M13 | MERV 13 | 85-90% | 5 | 2mm | 95gsm |

| HF-M14 | MERV 14 | 90-95% | 6 | 2.5mm | 135gsm |

PRODUCT DETAILS