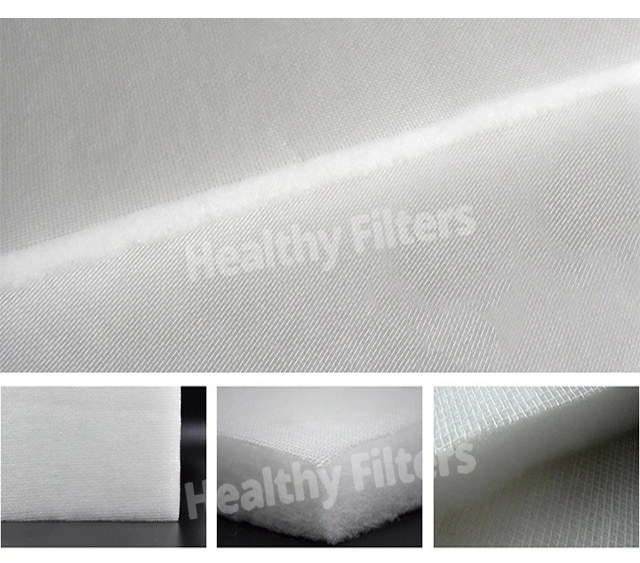

Retardant Material High Temperature Fiberglass Ceiling Filter Filter Media Synthetic Fiber-Based Nonwoven Filter Media

Pre-filter media is typically made from durable materials like synthetic fibers, metal mesh, or pleated paper, and can be either disposable or washable, depending on the application.

1. Made from robust materials like synthetic fibers, metal mesh, or pleated paper.

2. Many pre-filter media are washable, allowing for repeated use.

3. Simple to install in most HVAC systems with quick and hassle-free replacement processes.

- Overview

- Parameter

- Inquiry

- Related Products

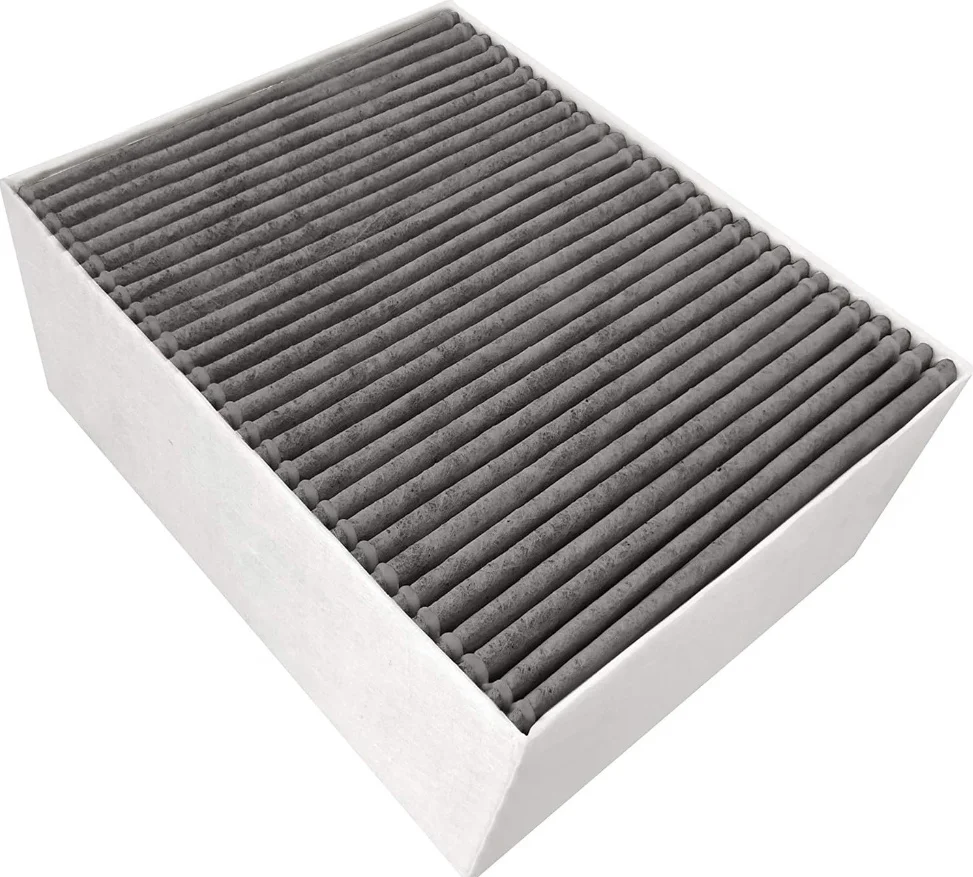

High Temperature Fiberglass Filter Media is a type of filter material specifically designed for high-temperature environments. Its main component is fiberglass, which can maintain its structure and performance under high temperatures. This material is made of glass fiber, laminated with non-woven fabric, and fixed with an aluminum expansion net, making it resistant to deformation. It can withstand high temperatures up to 300℃ and has good chemical resistance. This filter media is widely used in various industrial fields such as metallurgy, chemical processing, power generation, cement production, and waste incineration.

High-temperature fiberglass filter media possess multiple exceptional characteristics and advantages, including high temperature resistance, chemical corrosion resistance, high mechanical strength, low pressure drop, and excellent stability. It can operate at temperatures up to several hundred degrees Celsius, making it suitable for environments with corrosive gases and liquids, and it can withstand high pressure and mechanical stress generated in industrial processes. Additionally, this filter media offers good permeability and low pressure drop, effectively reducing system energy consumption. It maintains dimensional stability and physical properties at high temperatures, resisting aging and deformation. Consequently, it finds extensive applications in high-temperature flue gas filtration, air purification, liquid filtration, and dust removal equipment.

FEATURES

● Achieves 100% capture rate for dust particles larger than 5μm due to glue treatment

● Filter fibers are progressively denser, allowing for layered filtration

● High dust-holding capacity and extended service life

● Stable structure with uniform air permeability for consistent airflow diffusion

● Low initial resistance, with strong elasticity and crease resistance

● Treated for fire resistance, with a flame retardant rating up to S2 level

● Free from silicone

● Size:Customized

APPLICATIONS

Mainly used in spraying systems and paint booths with strict fire protection requirements.

It is used in the hot air ovens of paint factories to filter tar, soot, dust, and other particles generated in high-temperature drying rooms, preventing surface damage

SPECIFICATIONS

| Type | Thickness(mm) | Test Air Velocity (m/s) | Rated Air Flow(m3/h) | Average arrestance (EN779) | Initial Resistance(Pa) | Final Resistance (Pa ) | Dust Holding Capacity(g/m2) | FiltrationClass |

| HF-10 | 5 | 1.5 | 5400 | 65% | 15 | 250 | 400 | G2 |

| HF-20 | 10 | 1.5 | 5400 | 70% | 18 | 250 | 420 | G2 |

| HF-30 | 15 | 1.5 | 5400 | 80% | 20 | 250 | 520 | G3 |

| HF-40 | 20 | 1.5 | 5400 | 90% | 25 | 250 | 630 | G4 |

PRODUCT DETAILS