Separated HEPA Filter Corrugating Machine For Paper or Aluminum

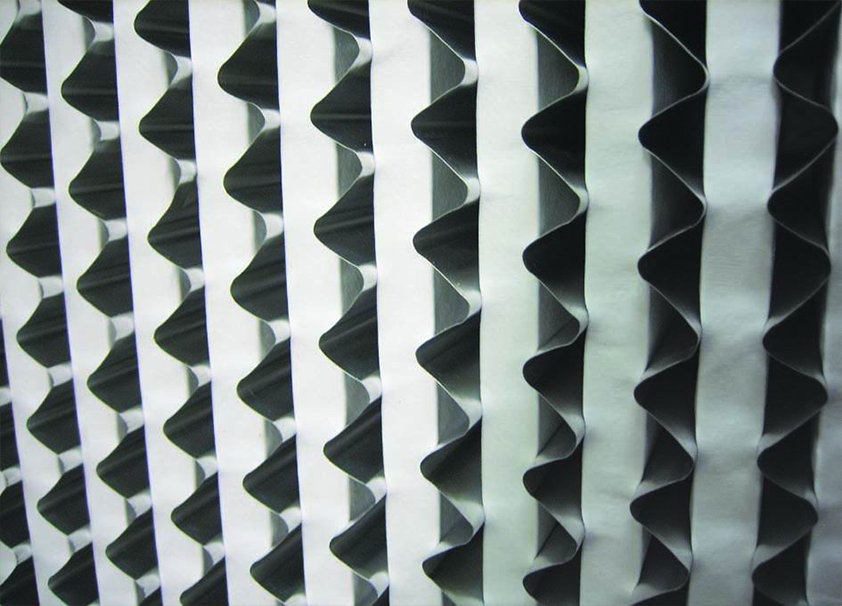

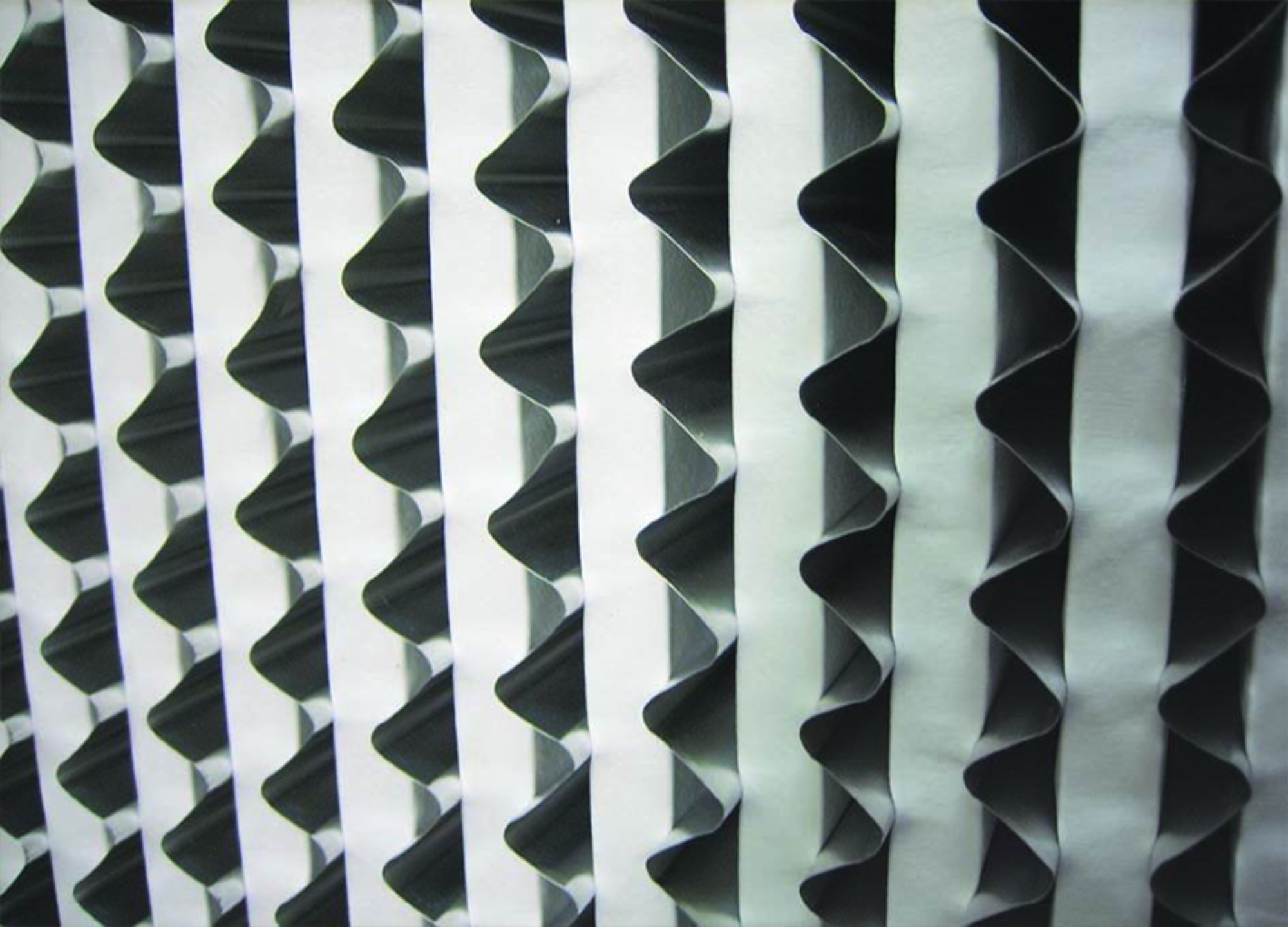

It is technically used in shaping the aluminum foil corrugation of separated high efficiency filter. We can customize the rollers according to the pleating height and pitch of waves.

- Overview

- Inquiry

- Related Products

The equipment is mainly used to produce corrugated partition with partition filter, suitable for aluminum foil and paper. Different corrugated heights can be adjusted by changing the corrugated mold.

Selectable width:300mm

SPECIFICATION

● Processing height: 50-285mm

● Corrugated height: 3mm/5mm/8mm

● Control system: PLC+Servo motor system

● Disruption agency: Pneumatic, spring compression knife set

● Conveying body: synchronized belt

● Material piling agency: Rodless cylinder

● Cutting length: 100~780mm

● Voltage: 220V

● Dimension: L: 4000 W: 1100 H: 1300mm

● Weight:600KG

FEATURES

1.The length can be set freely and cut off automatically.

2.The roller speed can be controlled through variable speed motor to accommodate different working conditions.

3.It is equipped with the aluminum edge double device while corrugating which prevent the fiber glass form breaking.

4.High efficiency and simple operation.

5.Use the gathering cylinder to collect products into the container.

APPLICATIONS

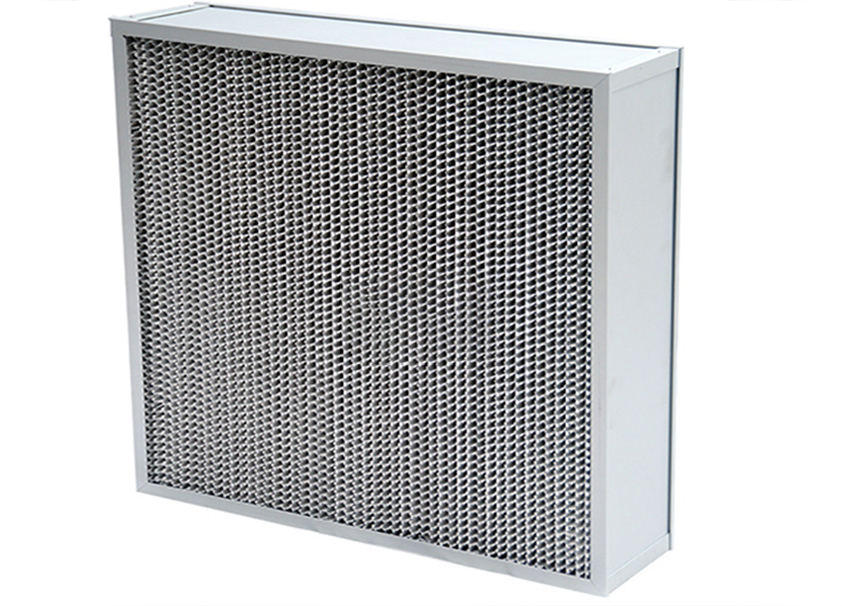

1.HEPA Filter Manufacturing

This machine is specifically designed to produce high-efficiency particulate air (HEPA) filters, which are critical for applications requiring high levels of air purity. It can corrugate both paper and aluminum, making it versatile for different types of filter media.

2.Air Purification Systems

The corrugation process enhances the surface area of filter materials, improving their ability to trap airborne particles. This makes the machine ideal for producing filters used in air purifiers for residential, commercial, and industrial environments.

3.Cleanroom Environments

HEPA filters manufactured using this machine are essential in cleanrooms where maintaining extremely low levels of particulates, such as dust, airborne organisms, or vaporized particles, is crucial. Industries like semiconductor manufacturing, biotechnology, and pharmaceuticals rely on these filters.

4.HVAC Systems

The machine can produce filters used in heating, ventilation, and air conditioning (HVAC) systems to ensure clean air circulation within buildings, enhancing indoor air quality and protecting sensitive equipment and processes.

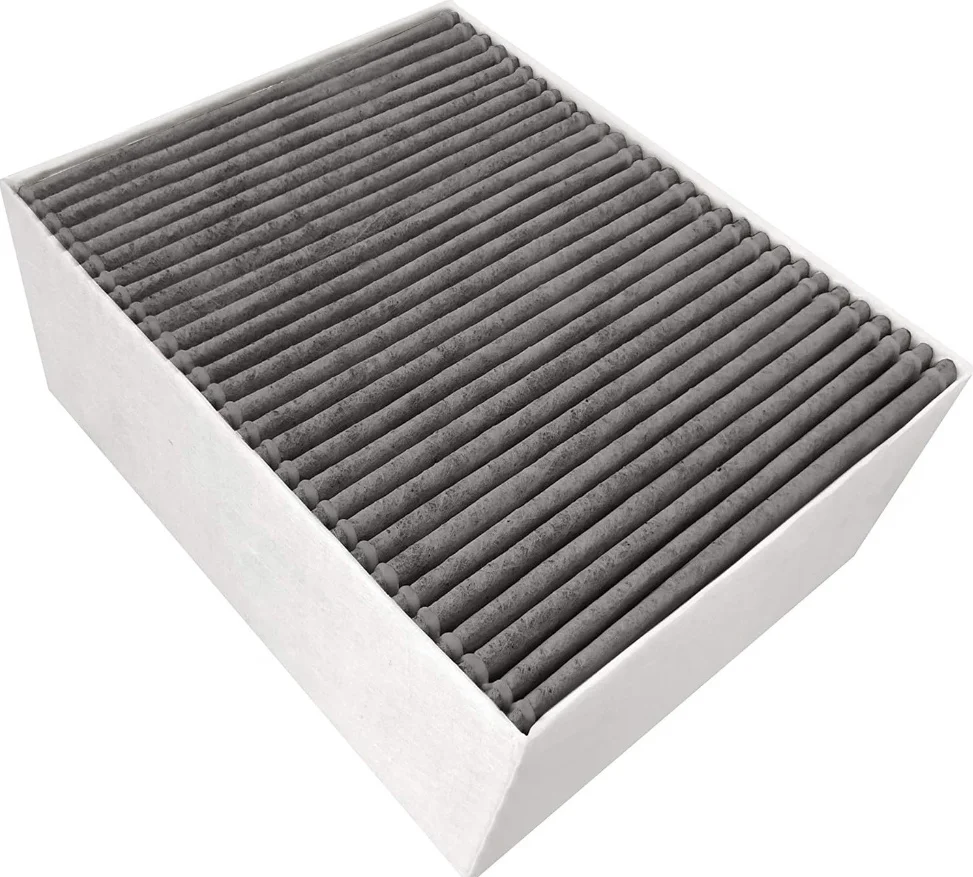

5.Automotive Industry

The machine's capability to corrugate durable materials like aluminum makes it suitable for producing HEPA filters used in automotive applications, such as cabin air filters that remove contaminants from the air entering the vehicle's interior.

6.Medical Facilities

HEPA filters produced by this machine are used in hospitals and clinics to create sterile environments. They help prevent the spread of airborne pathogens and ensure clean air in operating rooms, intensive care units, and other critical areas.

7.Aerospace Industry

The aerospace industry requires highly efficient air filtration systems for aircraft cabins. This machine can produce the specialized filters needed to maintain air quality and passenger safety at high altitudes.

8.Laboratory Equipment

Filters made using this machine are used in various laboratory equipment that requires controlled air environments, such as fume hoods and biological safety cabinets, to protect both the user and the experiments from contamination.

9.Industrial Processes

Many industrial processes, including paint booths, chemical processing, and food production, require high-efficiency filtration to protect products and workers from airborne contaminants. This machine helps produce the necessary filters for these applications.

10.Residential Air Filtration

With increasing awareness of indoor air quality, this machine can produce HEPA filters for use in residential air purifiers, helping to remove allergens, dust, and other pollutants from the home environment.

PRODUCT DETAILS