The Significance of Industrial HEPA Filters in Ensuring Clean Air Quality for Industrial Settings

The most important thing in industrial environments is to have clean air that will protect workers’ health, enhance productivity, and keep manufactur-ing process intact. Since they are characterized by the release of potentially harmful particles, gases and contaminants, many industries can be very dangerous for humans and the life of their devices. From the wide range of air purification solutions available on the market, High Efficiency Particulate Air (HEPA) filters stand out as a key component towards achieving optimal indoor air quality in industries.

Understanding Industrial HEPA Filters:

Industrial HEPA filters have been designed with specificity to capture airborne particles efficiently. These filters often remove not less than 99.97% of particles measuring up to 0.3 µm in diameter or bigger through them hence called High Efficiency Particulate Air (HEPA) filters. This level of filtration becomes particularly significant in industries where even the tiniest dust or other particle can affect very delicate manufacturing processes or lead to serious diseases among employees.

Importance of Industrial HEPA Filters:

Health Protection for Workers: Exposure to airborne pollutants like dust, allergens, mold spores and toxic chemicals can cause respiratory illnesses as well as skin irritations among others. Consequently using industrial HEPA filters therefore reduces these harmful elements concentration resulting into more secure places for people work.

Product Quality Enhancement: In fact, it takes one tiny granule within any pharmaceutical facility when such facilities are used which may compromise all products from being consumed by patients because they have been rendered unfit for human consumption due contamination through dirt and bacteria.

Improving Energy Efficiency: Properly installed air filtration systems reduce the requirement for frequent cleaning and maintenance of HVAC units leading to enhanced energy efficiency over time across these systems Clean air enhances heat transfer by preventing fouling thus reducing energy usage during production processes.

Applications of Industrial HEPA Filters:

Semiconductor Manufacturing: This involves the production of a chip from silicon and other substances which are often done in extremely clean rooms.

Pharmaceutical Production: Medical devices and drugs must be kept away from contamination with sterile air.

Food and Beverage Processing: Food safety and quality standards are maintained by keeping allergens, dust, and other forms of contaminants out of the air.

Laboratories and Research Facilities: High-precision experiments often necessitate ultra-clean air to prevent contamination and ensure accurate results.

In conclusion, Industrial HEPA filters play an important role in ensuring that the air within industrial facilities is clean. They help keep out harmful particles from the surrounding environment thereby protecting workers’ health, improving product quality, extending service life for machinery, meeting regulatory requirements as well as reducing energy consumption.

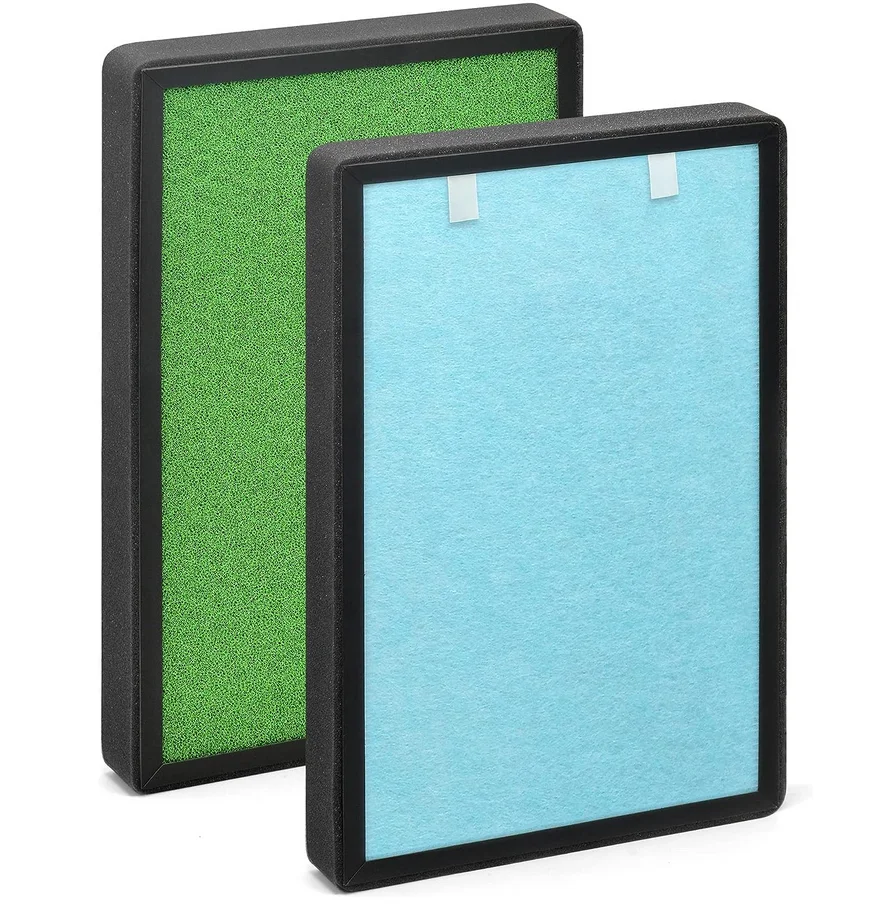

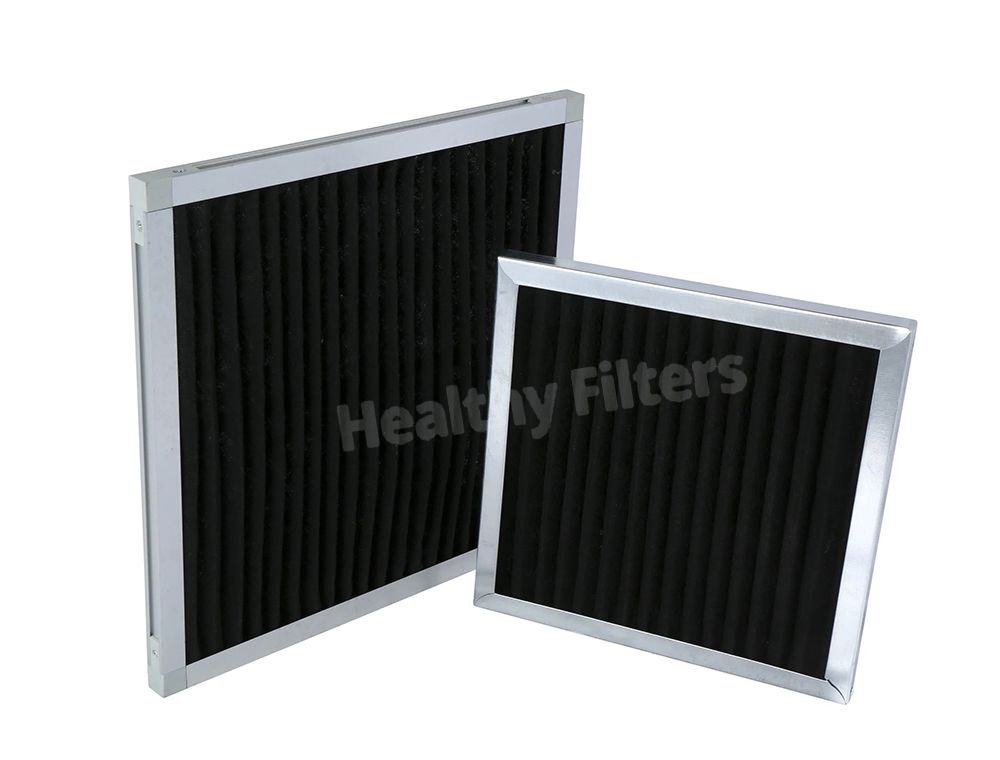

Recommended Products

Hot News

-

What You Need to Know About AIRCARE Humidifier Filters

2024-01-24

-

Filtration Show 2023 USA

2023-12-13

-

Filtech 2024 Germany

2023-12-13

-

Obtain Patent Certificate

2023-12-13