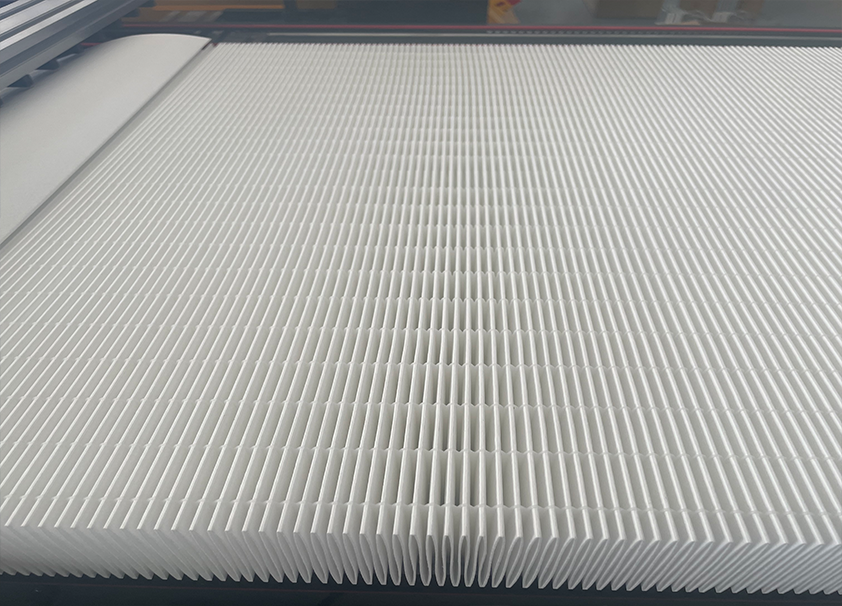

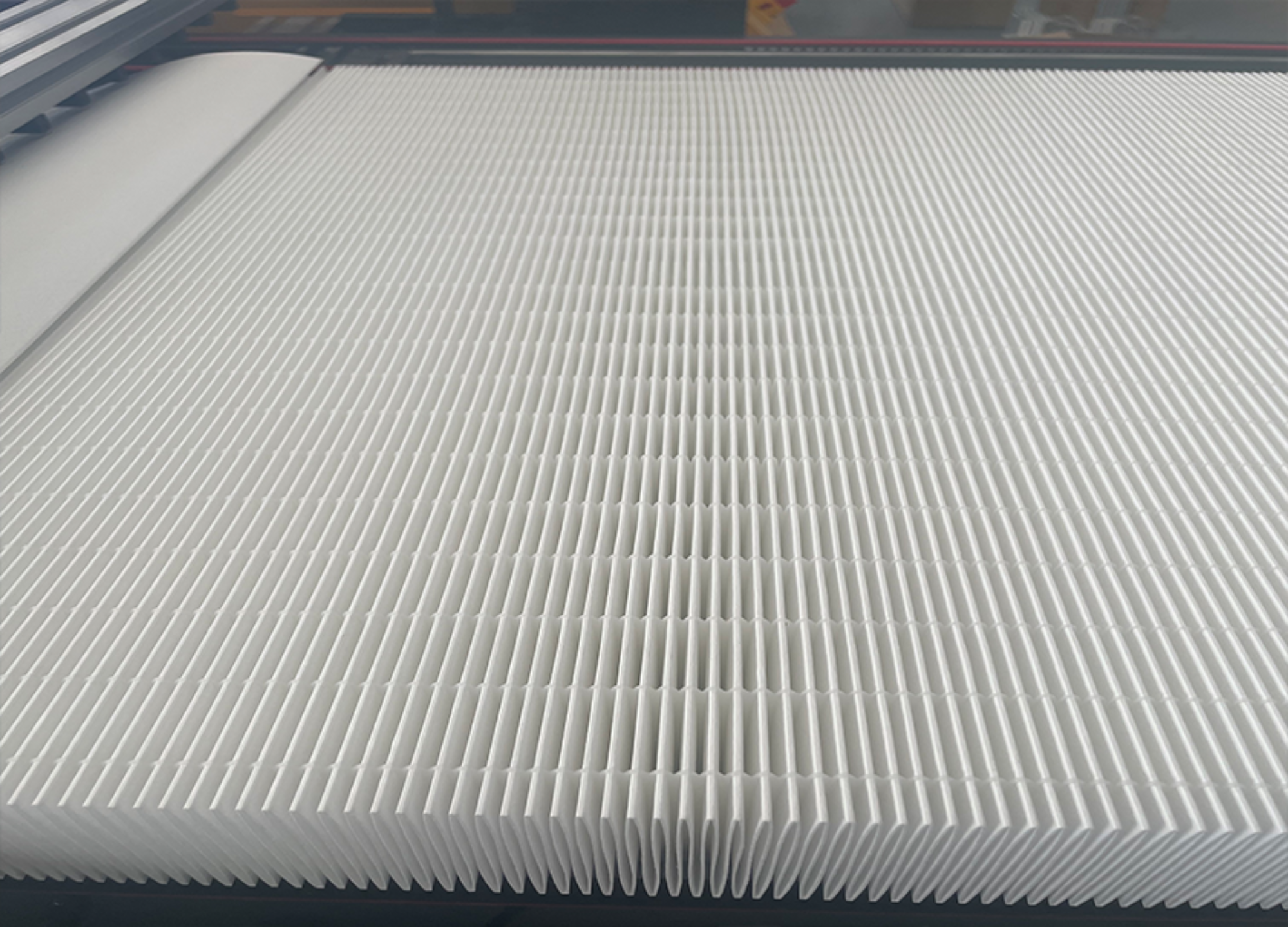

Automatic Air Filter Making Machine Knife Mini Pleating Machine

Pleating and Hotmelt dispensing on glass fiber for HEPA/ULPA filter pack production

6th Gen Machine-Filter Folding Paper Production Line without partition

- Overview

- Inquiry

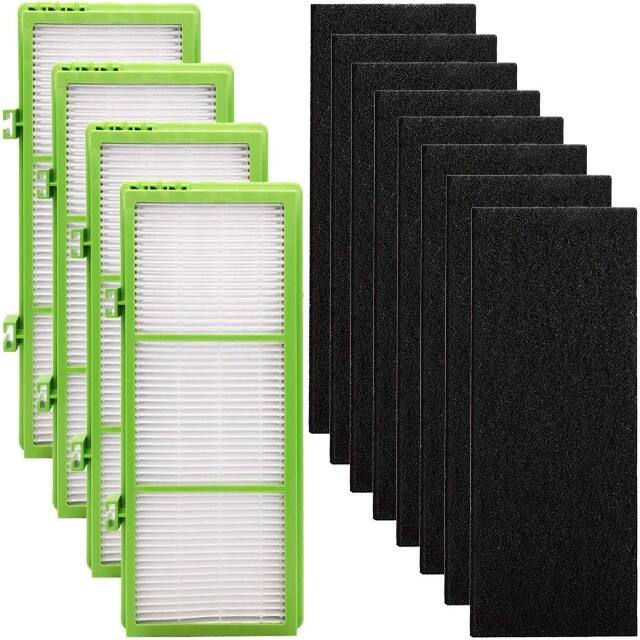

- Related Products

Healthy Filters S1300S equipment is used to produce high efficiency filters without baffles. The H1300H model before 2023 will be upgraded. This equipment will be put into the market in 2023. Compared with the previous equipment (H model), it has optimized the program control software, tension control, CNC high-precision processing parts, and international brand standard parts. The equipment is easier to operate and has the advantages of less loss of filter paper.

Selectable width:700mm/1000mm/1300mm/1500mm

FEATURES

● Small resistance

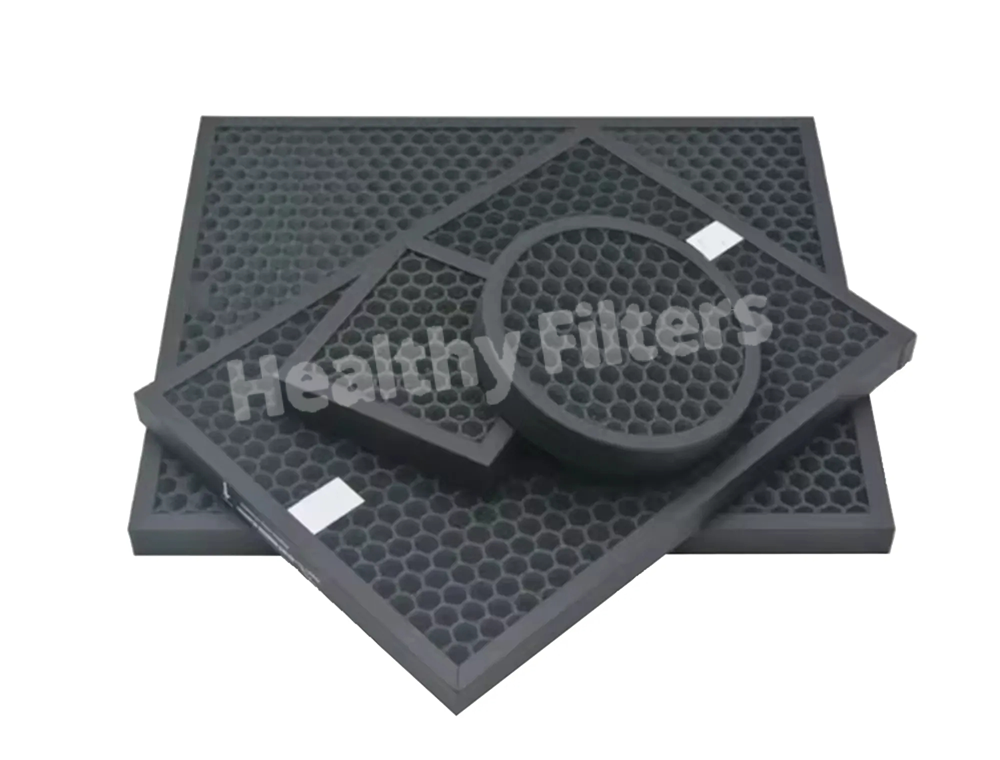

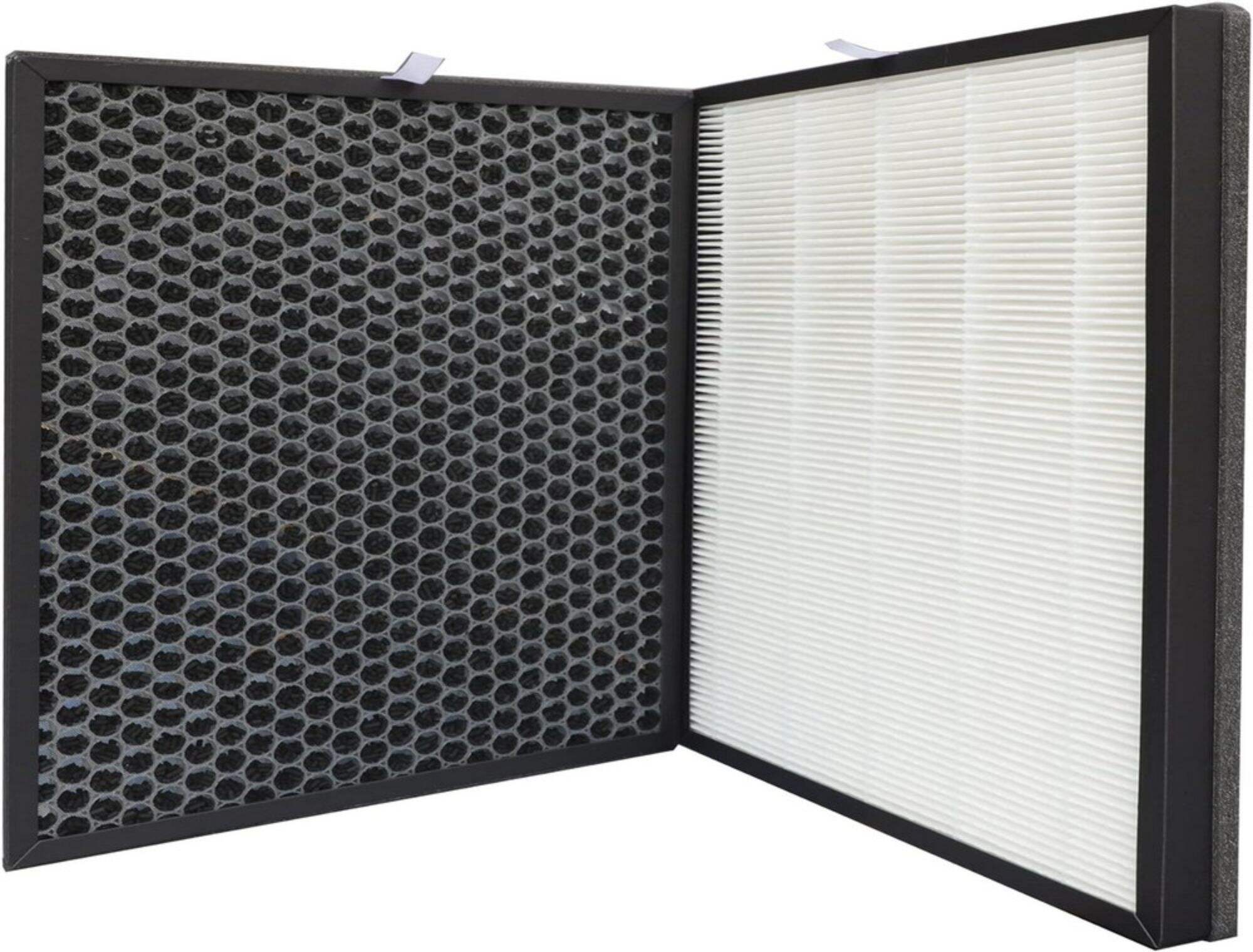

● Made of 2/3/4 layers PP fabric+MB fabric +Non-woven fabric

● High dust holding capacity

● Uniform color according to EN779 distinguish

● Safe material

● non-toxic and odorles

● Color is customizable

● Processing width:1280mm widest

● Paper folding height:18mm-120mm(producible within the range, for other sizes, it offers customization solution)

● Production speed:100-220 folds/production speed per min

● Quantity of glue lines:52 lines-2 rows, interval at 25.4mm

● Glue line switch control: solenoid valve one-to-one control, glue spraying function has intermittent and fold counting function

● Capacity of glue smelting machine:70LX2(Brand:domestic or Phalbok)

● Quantity of cutting knife:6 pieces

● Material feeding means:Pneumatic auxiliary feeding

● Unwinding tension control:automatic

● Glue spraying cooling: 6 sets of fans in total;

● Air cooling equipment:4 sets of air cooler

● Safety protection: mechanical operation and dangerous places are equipped with alarm and emergency stop device

● Voltage:380V Power:32KW

● Dimension:L:7500mm W:2500mm H:1800mm

● Gas consumption:0.3m3/min

● Weight:1900KG

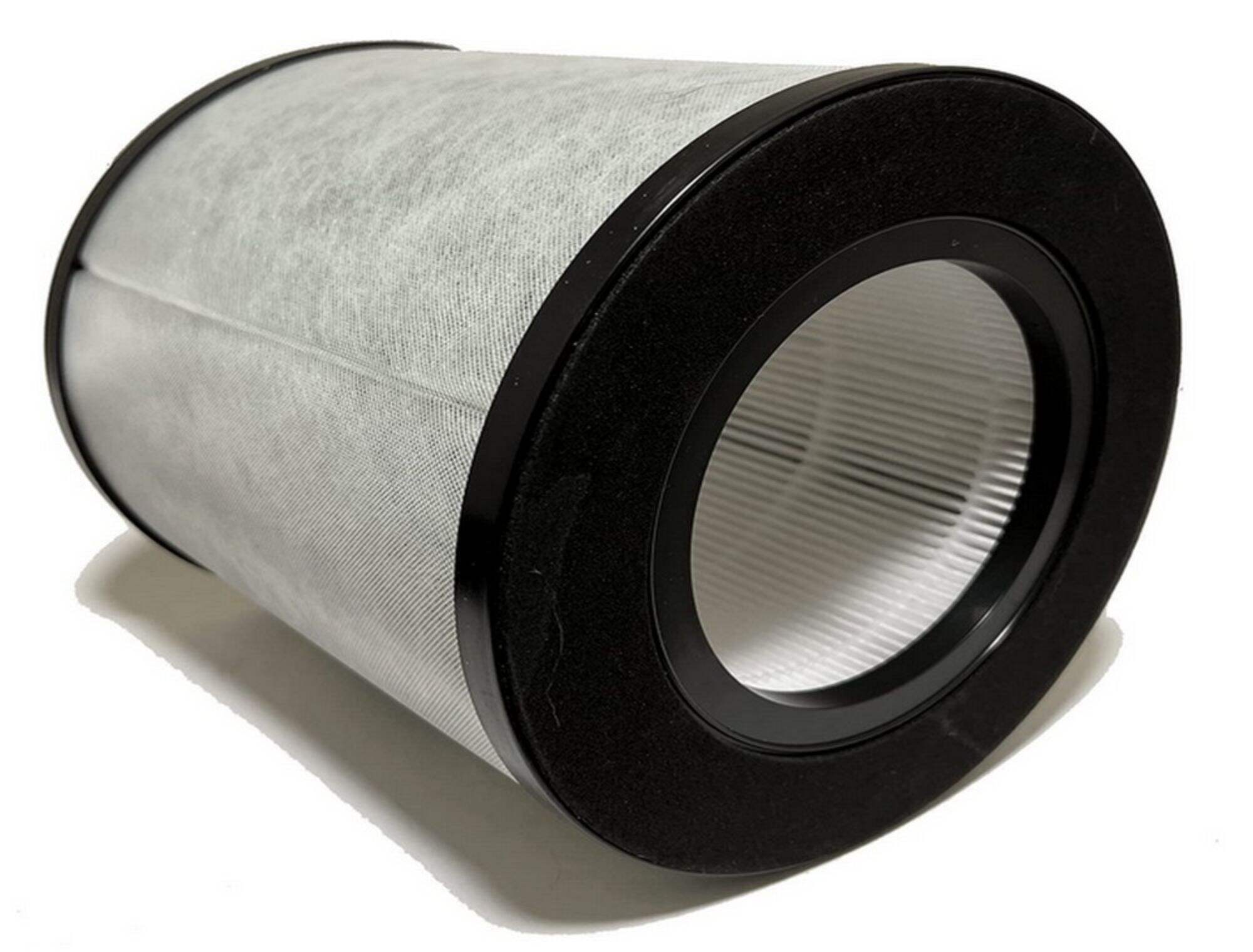

APPLICATIONS

1.HEPA and ULPA Filters:

Used in cleanrooms, hospitals, and laboratories where high air quality standards are essential.

2.HVAC Filters:

Used in heating, ventilation, and air conditioning systems to improve air quality and system efficiency.

3.Automotive Air Filters:

Used in vehicle engine intake systems and cabin air filtration systems to ensure clean air enters the engine and cabin.

4.Industrial Filters:

Used in various industrial environments, including manufacturing plants, food processing facilities, and chemical plants, to filter dust, particles, and pollutants from the air.

5.Home Air Purifier Filters:

Used in household air purification devices to help remove indoor air pollutants, allergens, and odors.

6.Electronics Equipment Filters:

Used in cooling systems of electronic and telecom equipment to prevent dust and particles from entering the devices.

7.Pharmaceutical and Medical Equipment Filters:

Used in pharmaceutical production and medical equipment to ensure clean air in production environments and inside equipment.

8.Paint Booth Filters:

Used in automotive and other industrial paint booths to prevent dust and particles from contaminating paint jobs.

9.Spray Paint Room Filters:

Used in spray painting operations to maintain air quality and prevent particles from contaminating painted surfaces.

PRODUCT DETAILS